- Outer Diameter (D)(φ)

- 5

- Flute Length (ℓ)(mm)

- 7.5

- Shank Diameter (d)(mm)

- 6

- Overall Length (L)(mm)

- 100

- Length Under Neck (ℓ1)(mm)

- 35

- Geometry

- Torsion Angle (θ)

- Additional Classification

- Tipo

- Giorni di spedizione est.

- Tutti

- Entro 5 giorni lavorativi

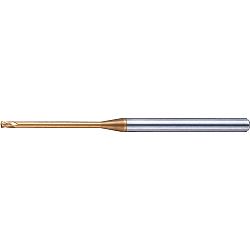

TSC series carbide long neck square end mill, 4-flute / long neck model (TSC-PEM4LB5-35)

Disegno schematico

Ulteriori informazioni

Informazioni di base

[Caratteristiche] -Dimostra elevate prestazioni nella lavorazione di acciai generici, EN 1.4301 Equiv. (SUS304) e acciai trattati termicamente (fino a 50 HRC) -Può selezionare la lunghezza ottimale del corpo per la lavorazione di parti profonde del pezzo -Ottima per la lavorazione nel campo di tornitura medio-basso grazie all'angolo di spirale universale di 30° -Completa il rivestimento con un'elevata resistenza all'ossidazione e un'alta durezza, e raggiunge una lunga durata. Efficace nella lavorazione ad alta velocità e nella lavorazione a secco grazie alle caratteristiche del rivestimento.

Specifiche e prezzo

Specifiche

Model Number

TSC-PEM4LB (Sharp Edge / Stocked Product) / TSC-EM4LB (Standard / Stocked Product)

| Outer Diameter D |

Length Under Neck ℓ1 |

Standard | Sharp Edge | Flute Length ℓ |

Under Neck Diameter d1 |

Overall Length L |

Shank Diameter d |

Actual Effective Length Depends on Work Inclination Angle | Figure | |||

| 30' | 1° | 2° | 3° | |||||||||

| 1 | 4 | ● | ● | 1.5 | 0.95 | 50 | 4 | 4.19 | 4.40 | 4.88 | 5.49 | 1 |

| 6 | ● | ● | 6.28 | 6.59 | 7.32 | 8.24 | ||||||

| 8 | ● | ● | 8.38 | 8.79 | 9.76 | 10.98 | ||||||

| 10 | ● | ● | 10.47 | 10.99 | 12.21 | 13.73 | ||||||

| 12 | ● | ● | 12.57 | 13.19 | 14.65 | 16.48 | ||||||

| 1.2 | 6 | ● | ● | 1.8 | 1.15 | 50 | 4 | 6.28 | 6.59 | 7.32 | 8.24 | 1 |

| 8 | ● | ● | 8.38 | 8.79 | 9.76 | 10.98 | ||||||

| 10 | ● | ● | 10.47 | 10.99 | 12.21 | 13.73 | ||||||

| 12 | ● | ● | 12.57 | 13.19 | 14.65 | 16.48 | ||||||

| 16 | ● | ● | 16.75 | 17.58 | 19.53 | 21.97 | ||||||

| 1.3 | 6 | No Standards | ● | 1.9 | 1.25 | 50 | 4 | 6.28 | 6.59 | 7.32 | 8.24 | 1 |

| 10 | No Standards | ● | 10.47 | 10.99 | 12.21 | 13.73 | ||||||

| 1.4 | 6 | No Standards | ● | 2.1 | 1.35 | 50 | 4 | 6.28 | 6.59 | 7.32 | 8.24 | 1 |

| 8 | No Standards | ● | 8.38 | 8.79 | 9.76 | 10.98 | ||||||

| 10 | No Standards | ● | 10.47 | 10.99 | 12.21 | 13.73 | ||||||

| 14 | No Standards | ● | 14.66 | 15.39 | 17.09 | 19.22 | ||||||

Model Number

TSC-PEM4LB (Sharp Edge / Stocked Product) / TSC-EM4LB (Standard / Stocked Product)

| Outer Diameter D |

Length Under Neck ℓ1 |

Standard | Sharp Edge | Flute Length ℓ |

Under Neck Diameter d1 |

Overall Length L |

Shank Diameter d |

Actual Effective Length Depends on Work Inclination Angle | Figure | |||

| 30' | 1° | 2° | 3° | |||||||||

| 1.5 | 6 | ● | ● | 2.3 | 1.45 | 50 | 4 | 6.28 | 6.59 | 7.32 | 8.24 | 1 |

| 8 | ● | ● | 8.38 | 8.79 | 9.76 | 10.98 | ||||||

| 10 | ● | ● | 10.47 | 10.99 | 12.21 | 13.73 | ||||||

| 12 | ● | ● | 12.57 | 13.19 | 14.65 | 16.48 | ||||||

| 14 | ● | ● | 14.66 | 15.39 | 17.09 | 19.22 | ||||||

| 16 | ● | ● | 16.75 | 17.58 | 19.53 | 21.97 | ||||||

| 18 | ● | ● | 70 | 18.85 | 19.78 | 21.97 | 24.71 | |||||

| 20 | ● | ● | 20.94 | 21.98 | 24.41 | Without Interference | ||||||

| 1.6 | 6 | No Standards | ● | 2.4 | 1.55 | 50 | 4 | 6.28 | 6.59 | 7.32 | 8.24 | 1 |

| 8 | No Standards | ● | 8.38 | 8.79 | 9.76 | 10.98 | ||||||

| 10 | No Standards | ● | 10.47 | 10.99 | 12.21 | 13.73 | ||||||

| 12 | No Standards | ● | 12.57 | 13.19 | 14.65 | 16.48 | ||||||

| 14 | No Standards | ● | 14.66 | 15.39 | 17.09 | 19.22 | ||||||

| 1.7 | 6 | No Standards | ● | 2.5 | 1.65 | 50 | 4 | 6.28 | 6.59 | 7.32 | 8.24 | 1 |

| 16 | No Standards | ● | 16.75 | 17.58 | 19.53 | 21.97 | ||||||

| 1.8 | 6 | No Standards | ● | 2.7 | 1.75 | 50 | 4 | 6.28 | 6.59 | 7.32 | 8.24 | 1 |

| 8 | No Standards | ● | 8.38 | 8.79 | 9.76 | 10.98 | ||||||

| 10 | No Standards | ● | 10.47 | 10.99 | 12.21 | 13.73 | ||||||

| 12 | No Standards | ● | 12.57 | 13.19 | 14.65 | 16.48 | ||||||

| 14 | No Standards | ● | 14.66 | 15.39 | 17.09 | 19.22 | ||||||

| 16 | No Standards | ● | 16.75 | 17.58 | 19.53 | Without Interference | ||||||

| 20 | No Standards | ● | 70 | 20.94 | 21.98 | 24.41 | Without Interference | |||||

| 25 | No Standards | ● | 26.18 | 27.47 | 30.51 | Without Interference | ||||||

| 2 | 6 | ● | ● | 3 | 1.95 | 50 | 4 | 6.28 | 6.59 | 7.32 | 8.24 | 1 |

| 8 | ● | ● | 8.38 | 8.79 | 9.76 | 10.98 | ||||||

| 10 | ● | ● | 10.47 | 10.99 | 12.21 | 13.73 | ||||||

| 12 | ● | ● | 12.57 | 13.19 | 14.65 | 16.48 | ||||||

| 14 | ● | ● | 14.66 | 15.39 | 17.09 | 19.22 | ||||||

| 16 | ● | ● | 16.75 | 17.58 | 19.53 | Without Interference | ||||||

| 18 | ● | ● | 70 | 18.85 | 19.78 | 21.97 | Without Interference | |||||

| 20 | ● | ● | 20.94 | 21.98 | 24.41 | Without Interference | ||||||

| 25 | ● | ● | 26.18 | 27.47 | Without Interference | Without Interference | ||||||

| 30 | ● | ● | 31.41 | 32.97 | Without Interference | Without Interference | ||||||

| 2.5 | 8 | ● | ● | 3.8 | 2.4 | 50 | 4 | 8.38 | 8.79 | 9.76 | 10.98 | 1 |

| 12 | ● | ● | 12.57 | 13.19 | 14.65 | Without Interference | ||||||

| 16 | ● | ● | 16.75 | 17.58 | 19.53 | Without Interference | ||||||

| 20 | ● | ● | 70 | 20.94 | 21.98 | Without Interference | Without Interference | |||||

| 25 | ● | ● | 26.18 | 27.47 | Without Interference | Without Interference | ||||||

Model Number

TSC-PEM4LB (Sharp Edge / Stocked Product) / TSC-EM4LB (Standard / Stocked Product)

| Outer Diameter D |

Length Under Neck ℓ1 |

Standard | Sharp Edge | Flute Length ℓ |

Under Neck Diameter d1 |

Overall Length L |

Shank Diameter d |

Actual Effective Length Depends on Work Inclination Angle | Figure | |||

| 30' | 1° | 2° | 3° | |||||||||

| 3 | 8 | No Standards | ● | 4.5 | 2.9 | 50 | 6 | 8.38 | 8.79 | 9.76 | 10.98 | 1 |

| 12 | ● | ● | 12.57 | 13.19 | 14.65 | 16.48 | ||||||

| 16 | ● | ● | 70 | 16.75 | 17.58 | 19.53 | 21.97 | |||||

| 20 | ● | ● | 20.94 | 21.98 | 24.41 | 27.46 | ||||||

| 25 | ● | ● | 26.18 | 27.47 | 30.51 | Without Interference | ||||||

| 30 | ● | ● | 31.41 | 32.97 | 36.62 | Without Interference | ||||||

| 40 | ● | ● | 100 | 41.88 | 43.96 | Without Interference | Without Interference | |||||

| 3.5 | 16 | No Standards | ● | 5.5 | 3.35 | 70 | 6 | 16.75 | 17.58 | 19.53 | 21.97 | 1 |

| 25 | No Standards | ● | 26.18 | 27.47 | 30.51 | Without Interference | ||||||

| 35 | No Standards | ● | 100 | 36.65 | 38.46 | Without Interference | Without Interference | |||||

| 4 | 12 | No Standards | ● | 6 | 3.8 | 50 | 6 | 12.57 | 13.19 | 14.65 | 16.48 | 1 |

| 16 | ● | ● | 16.75 | 17.58 | 19.53 | Without Interference | ||||||

| 20 | ● | ● | 70 | 20.94 | 21.98 | 24.41 | Without Interference | |||||

| 30 | ● | ● | 31.41 | 32.97 | Without Interference | Without Interference | ||||||

| 35 | No Standards | ● | 100 | 36.65 | 38.46 | Without Interference | Without Interference | |||||

| 40 | ● | ● | 41.88 | 43.96 | Without Interference | Without Interference | ||||||

| 45 | No Standards | ● | 47.12 | 49.45 | Without Interference | Without Interference | ||||||

| 50 | No Standards | ● | 52.35 | 54.95 | Without Interference | Without Interference | ||||||

| 5 | 16 | ● | ● | 7.5 | 4.8 | 70 | 6 | 16.75 | 17.58 | Without Interference | Without Interference | 1 |

| 25 | ● | ● | 26.18 | 27.47 | Without Interference | Without Interference | ||||||

| 35 | ● | ● | 100 | 36.65 | Without Interference | Without Interference | Without Interference | |||||

| 50 | ● | ● | 52.35 | Without Interference | Without Interference | Without Interference | ||||||

| 6 | 20 | ● | ● | 9 | 5.8 | 70 | 6 | Without Interference | Without Interference | Without Interference | Without Interference | 2 |

| 30 | ● | ● | Without Interference | Without Interference | Without Interference | Without Interference | ||||||

| 40 | ● | ● | 100 | Without Interference | Without Interference | Without Interference | Without Interference | |||||

| 50 | ● | ● | Without Interference | Without Interference | Without Interference | Without Interference | ||||||

Model Number

LN-TSC-PEM4S (Sharp Edge / Manufactured Product) / EM4S (Standard / Manufactured Product)

| Outer Diameter D |

Length Under Neck ℓ1 1 mm Increment Designation |

Standard | Sharp Edge | Flute Length ℓ |

Under Neck Diameter d1 |

Overall Length L |

Shank Diameter d |

Figure |

| 1.5 | 8 ~ 20 | ● | ● | 3 | 1.45 | 40 | 4 | 3 |

| 2 | 9 ~ 21 | ● | ● | 4 | 1.95 | 40 | 4 | 3 |

| 2.5 | 10 ~ 22 | ● | ● | 5 | 2.4 | 40 | 4 | 3 |

| 3 | 11 ~ 21 | ● | ● | 6 | 2.9 | 45 | 6 | 3 |

| 3.5 | 12 ~ 22 | ● | ● | 7 | 3.3 | 45 | 6 | 3 |

| 4 | 13 ~ 23 | ● | ● | 8 | 3.8 | 45 | 6 | 3 |

| 5 | 15 ~ 25 | ● | ● | 10 | 4.8 | 45 | 6 | 3 |

[ ! ]When ordering manufactured products, be sure to confirm the ordering examples as the model numbers differ as below when ordering a stocked product.

(1) "LN-" is prepended to the start of the model number. (2) "S" is appended to the end of the model number

For Cutting Conditions, Refer to >>Click here.

Caratteristiche ed esempi di utilizzo

Più Informazioni

● The ideal under-neck length can be selected for workpiece machining in deep areas.

● It has a TS film coating with much greater oxidation resistance and hardness than conventional films, yielding a longer operational life and is ideal for high speed machining / dry machining.