Configura

- Outer Diameter (D)(φ)

- 4

- R Size(mm)

- 0.2

- Flute Length (ℓ)(mm)

- 18

- Overall Length (L)(mm)

- 60

- Shank Diameter (d)(mm)

- 6

- Tipo

- Giorni di spedizione est.

- Tutti

- Entro 5 giorni lavorativi

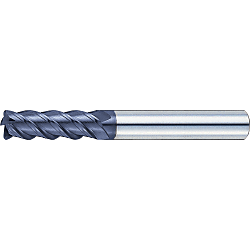

XAL series carbide radius end mill, 4-flute, 45° torsion / regular model (XAL-CR-HEM4R4-R0.2)

Disegno schematico

Ulteriori informazioni

Informazioni di base

4-Flute Radius for High-Efficiency and High-Speed Machining

Specifiche e prezzo

Specifiche

Model Number

XAL-CR-HEM4R

| Outer Diameter D |

Radius R |

Flute Length ℓ |

Overall Length L |

Shank Diameter d |

Figure | |||

| 4 | 0.2 | 0.5 | 1 | 18 | 60 | 6 | 1 | |

| 5 | 0.5 | 1 | 21 | 60 | 6 | 1 | ||

| 6 | 0.5 | 1 | 21 | 60 | 6 | 2 | ||

| 8 | 0.5 | 1 | 2 | 26 | 75 | 8 | 2 | |

| 10 | 0.5 | 1 | 2 | 34 | 90 | 10 | 2 | |

| 12 | 0.5 | 1 | 2 | 38 | 100 | 12 | 2 | |

For Cutting Conditions, Refer to >>Click here.

Caratteristiche ed esempi di utilizzo

Più Informazioni

● Capable of preventing chattering when used as a replacement for square end mills, allowing the expectations of a long operational life.

● The XAL coating with excellent lubricity delivers stable wear-resistant performance, especially when milling mild steel, giving improved shape accuracy to the machined objects.

● Delivers high-cost performance for pre-hardened steel, aluminum and copper alloys.

[ ! ]The XAL coating does not have conductive properties. Cannot be used with conduction model tool setters.