- Diametro collegamento

- Pressione di esercizio max.(MPa)

- 1

- Materiali involucro

- Resina

- Involucro in policarbonato

- Protezione coppa

- Meccanismo di scarico

- Direzione flusso

- Flusso inverso (da destra a sinistra)

- Direzione flusso

- Rubinetto di scarico

- Tipo manuale

- Manuale

- Manometro

- Con pressostato

- Pressostato digitale

- Size of Body

- 20

- Pressure Switch

- Residual Pressure Relief 3-Port Connection Valve

- Set Pressure

- Drain Outlet

- Pressure Unit

- Tipo

- CAD

- 2D

- 3D

- Giorni di spedizione est.

- Tutti

- Entro 26 giorni lavorativi

AC20D-B to AC40D-B, nuovo modello modulare, filtro regolatore + Microfiltro disoleatore (AC20D-02E1-R-B)

Informazioni sul prodotto

Air Combination, Filter Regulator + Mist Separator, AC20D-B to AC40D-B Specifications

AC40D-B external appearance

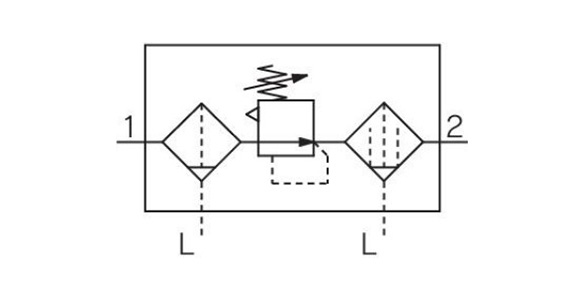

JIS symbol

Standard Specifications

| Model | AC20D-B | AC30D-B | AC40D-B | AC40D-06-B | |

|---|---|---|---|---|---|

| Components | Filter regulator [AW] | AW20-B | AC30-B | AW40-B | AW40-06-B |

| Mist Separator [AFM] | AFM20-A | AFM30-A | AFM40-A | AFM40-06-A | |

| Port size | 1/8, 1/4 | 1/4, 3/8 | 1/4 / 3/8 / 1/2 | 3/4 | |

| Pressure Gauge Connection Port Size [AW]*1 | 1/8 | ||||

| Fluid | Air | ||||

| Ambient temperature and working fluid temperature Note 2) | -5 to +60°C (no freezing) | ||||

| Proof pressure | 1.5 MPa | ||||

| Maximum operating pressure | 1.0 MPa | ||||

| Set Pressure Range [AW] | 0.05 to 0.85 MPa | ||||

| Filtration [AW/AFM] | AW: 5 μm, AFM: 0.3 μm (collection efficiency 99.9%) | ||||

| Rated Flow (L/min [ANR]) [AFM] *3 | 150 | 330 | 800 | 800 | |

| Outlet Oil Mist Density [AFM]*4 *5 | Max. 1.0 mg/m3(ANR) (≈ 0.8 ppm) | ||||

| Bowl Material [AW/AFM] | Polycarbonate | ||||

| Bowl Guard [AW/AFM] | Semi-standard (steel) | Standard equipment (polycarbonate) | |||

| Structure [AW] | Relieving type | ||||

| Weight (kg) | 0.32 | 0.62 | 1.15 | 1.25 | |

*1: For the specification with the square embedded type pressure gauge and the specification with the digital pressure switch, there are no pressure gauge connection screws.

*2: For the type with a digital pressure switch: -5 to +50°C.

*3: Conditions: Mist separator inlet pressure is 0.5 MPa. The rated flow varies according to the inlet pressure. Keep the air flow within the rated flow to prevent an outflow of oil to the outlet side.

*4: At compressor discharge concentration 30 mg/m3 (ANR)

*5: The bowl seal and other O-rings use a small amount of grease.

Dimensions

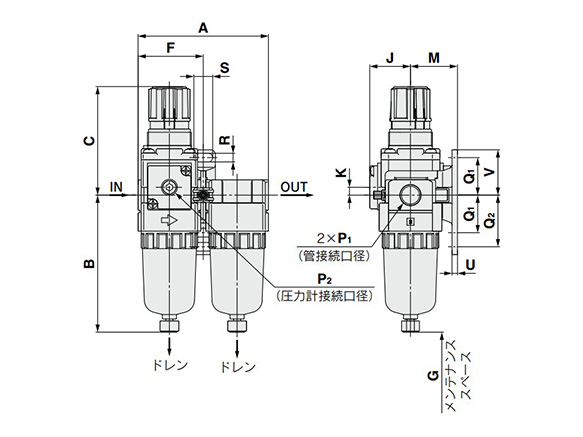

AC20D-B dimensional drawing

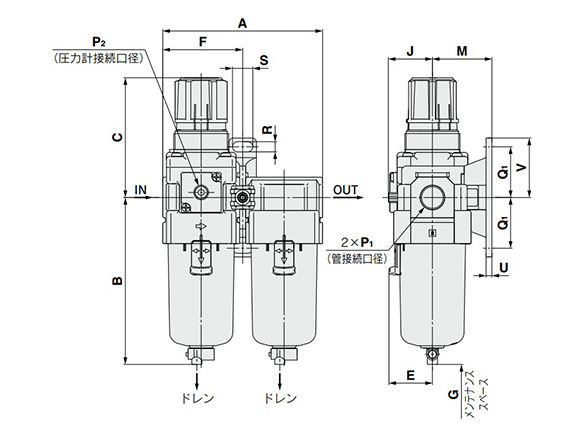

AC30D-B to AC40D-06-B dimensional drawing

(Unit: mm)

| Model | Standard specification | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| P1 | P2 | A | B | C* | E | F | G | J | K | Bracket mounting dimensions | |||||||

| M | Q1 | Q2 | R | S | U | V | |||||||||||

| AC20D-B | 1/8, 1/4 | 1/8 | 83.2 | 87.6 | 72.4 | - | 41.6 | 40 | 26 | 5 | 3 | ||||||

Ulteriori informazioni

Informazioni di base

[Features]

· Improved visibility and environmental resistance.

· The bowl is completely covered by transparent bowl guard.

& nbspThe inside can be seen from all angles (360°).

& nbspThe bowl is completely protected from the external environment, helping improve safety.

· Easy to work with.

& nbspThe element and bowl are combined into one unit, making it possible to replace the element by hand.

· The amount of space required for maintenance has been reduced.

Attenzione

- Refer to the catalog for details on product specifications.

- Product images may be representative. Refer to the manufacturer's catalog for details.