- Lavori di manutenzione: questa pagina non sarà disponibile dalle ore 3:00 21/4/2024 alle ore 0:00 (CET) 22/4/2024 per lavori di manutenzione al server. Ci scusiamo per questo inconveniente.

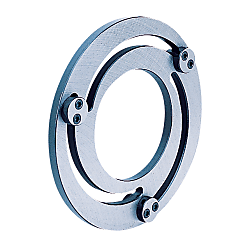

Elemento d'accoppiamento per mandrino

Fare clic sull'immagine per ingrandirla.

Cliccare sull´immagine per ingrandirla.

Codice componente

Qui sono indicati i codici componente

correlati al prodotto ricercato

Codice componente

|

|---|

| P-6-14 |

| P-6-17 |

| P-8-17 |

| P-8-19 |

| P-8-20 |

| P-10-19 |

| P-10-20 |

| P-12N-25 |

| S7-17 |

| S9-19 |

| Codice componente |

Prezzo unitario standard

| Quantità minima d'ordine | Sconto volumi elevati | Details Type | Compatible Chuck Outer Diameter (in.) | Pin Diameter (mm) | Outer Diameter (mm) | Maximum Machining Dimensions (mm) | Trusco Code | Mass (g) | |

|---|---|---|---|---|---|---|---|---|---|---|---|

208.43 € | 1 | 6 giorni | P Type (for Power Chuck) | 6 | 13.5 | 170 | 85 | 112-8388 | 1400 | ||

208.43 € | 1 | 6 giorni | P Type (for Power Chuck) | 6 | 16.5 | 170 | 85 | 112-8396 | 1400 | ||

272.32 € | 1 | 6 giorni | P Type (for Power Chuck) | 8 | 16.5 | 220 | 115 | 112-8418 | 2800 | ||

272.32 € | 1 | 6 giorni | P Type (for Power Chuck) | 8 | 18.5 | 220 | 115 | 112-8426 | 2800 | ||

272.32 € | 1 | 6 giorni | P Type (for Power Chuck) | 8 | 19.5 | 220 | 115 | 156-6679 | 2800 | ||

326.61 € | 1 | 6 giorni | P Type (for Power Chuck) | 10 | 18.5 | 260 | 148 | 112-8451 | 3500 | ||

326.61 € | 1 | 6 giorni | P Type (for Power Chuck) | 10 | 19.5 | 260 | 148 | 156-6687 | 3500 | ||

447.73 € | 1 | 6 giorni | P Type (for Power Chuck) | 12 | 24.5 | 318 | 186 | 405-5853 | 5300 | ||

282.82 € | 1 | 6 giorni | S type (for scroll chuck) | 7 | 16.5 | 230 | 115 | 103-2356 | 3100 | ||

342.12 € | 1 | 6 giorni | S type (for scroll chuck) | 9 | 18.5 | 270 | 148 | 103-2364 | 3900 |

Loading...

Informazioni di base

| Features | Soft jaw forming setup is done within 1 minute. Processing also completes in a short time. Even inexperienced people can do centering with single-action. Core runout accuracy is within 10 microns. Caliper measurements can be made without installing permanent tooling. When using, open the chuck, insert 3 stop pins of chuck mate in the mounting hole of soft jaw, and then tighten the chuck. In the case of tension chuck, perform the reverse operation. | Application | For soft jaw molding holder with chucked workpieces. |

|---|

Configura

Proprietà di base

-

Details Type

- P Type (for Power Chuck)

- S type (for scroll chuck)

-

Compatible Chuck Outer Diameter (in.)

- 6

- 7

- 8

- 9

- 10

- 12

-

Pin Diameter(mm)

- 13.5

- 16.5

- 18.5

- 19.5

- 24.5

-

Outer Diameter(mm)

- 170

- 220

- 230

- 260

- 270

- 318

-

Maximum Machining Dimensions(mm)

- 85

- 115

- 148

- 186

-

Trusco Code

-

Tipo

- P

- P-N

- S

Filtrare per giorni di spedizione standard

-

- Tutti gli articoli

- 6 giorni o meno

Attributi opzionali

- Specifiche e dimensioni di alcuni componenti potrebbero non essere illustrate in modo esauriente. Per i dettagli esatti, consultare i cataloghi dei produttori .