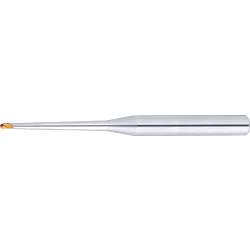

TSC Series Carbide Tapered Neck Ball End Mill, for High-Hardness Steel, 3-Flute / Tapered Neck Model

Fare clic sull'immagine per ingrandirla.

Cliccare sull´immagine per ingrandirla.

- Sconto volumi elevati

- TS

- High-Hardness Steel

- 3 Flutes

Codice componente

Qui sono indicati i codici componente

correlati al prodotto ricercato

| Codice componente |

Prezzo unitario standard

| Quantità minima d'ordine | Sconto volumi elevati | R Size (mm) | Flute Length (ℓ) (mm) | Overall Length (L) (mm) | Length Under Neck (ℓ1) (mm) | Shank Diameter (d) (mm) | R Precision (μm) | Neck Gradient θ1 | Outer Diameter D (mm) | Effective Length ℓ2 (mm) | Neck Diameter D1 (mm) | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

73.70 € | 1 | Disponibile | 5 giorni | 0.5 | 0.8 | 70 | 20 | 4 | ±0.005 | 1° | 1 | 2 | 1.63 | |

75.63 € | 1 | Disponibile | 5 giorni | 0.75 | 1.2 | 70 | 20 | 4 | ±0.005 | 1° | 1.5 | 3 | 2.09 | |

71.52 € | 1 | Disponibile | 5 giorni | 1 | 1.6 | 70 | 20 | 6 | ±0.005 | 1° | 2 | 4 | 2.56 | |

81.09 € | 1 | Disponibile | 5 giorni | 1 | 1.6 | 70 | 30 | 6 | ±0.005 | 1° | 2 | 4 | 2.91 | |

103.54 € | 1 | Disponibile | 5 giorni | 1 | 1.6 | 110 | 50 | 6 | ±0.005 | 1.5° | 2 | 4 | 4.41 | |

94.29 € | 1 | Disponibile | 5 giorni | 1 | 1.6 | 70 | 30 | 6 | ±0.005 | 2° | 2 | 4 | 3.82 | |

82.75 € | 1 | Disponibile | 5 giorni | 1 | 1.6 | 70 | 30 | 6 | ±0.005 | 3° | 2 | 4 | 4.73 | |

101.29 € | 1 | Disponibile | 5 giorni | 1.5 | 2.4 | 110 | 40 | 6 | ±0.005 | 0.5° | 3 | 6 | 4.78 | |

96.95 € | 1 | Disponibile | 5 giorni | 2 | 3.2 | 110 | 40 | 6 | ±0.005 | 1.5° | 4 | 8 | 5.12 | |

124.22 € | 1 | Disponibile | 5 giorni | 2 | 3.2 | 110 | 46 | 6 | ±0.005 | 1.5° | 4 | 8 | 5.33 | |

91.75 € | 1 | Disponibile | 5 giorni | 3 | 4.8 | 110 | 50 | 8 | -0.007 ~ +0.003 | 1° | 6 | 12 | 7.33 |

Loading...

Specifiche

| Model Number | Flute Length ℓ |

Overall Length L |

Shank Diameter d |

Figure | ||

| Outer Diameter D |

Radius R |

|||||

| TSC-SHP-CR-HFEM4B | 2 | 0.2 | 3 | 50 | 6 | 1 |

| 3 | 0.2 | 4.5 | 50 | 6 | 1 | |

| 4 | 0.5 | 6 | 50 | 6 | 1 | |

| 6 | 0.5 | 9 | 50 | 6 | 2 |

For Cutting Conditions, Refer to >>Click here.

Più Informazioni

● It is designed to have an ideal flute length, shank length and overall length, keeping in mind the usage of a shrink fit holder for processing.

● A radius (R) accuracy within 5 μm (our measured ratio) / shank diameter, tolerance h5 standard, has been adopted. The highly accurate tools with minimal quality variation are suitable for realizing high-accuracy, high-precision machining.

● Designed to have a blade shape with an emphasis on rigidity thanks to the radius (R) model negative blade, they are suitable for machining heat-treated steel / high hardness steel.

● The TS coat consisting of a nitride-based composite film with a fully crystalline structure means that it realizes a high oxidation resistance temperature and high hardness. It is ideal for high speed machining and dry machining of heat-treated / high hardness steel.

Informazioni di base

| Model | Tapered Neck Bore | Work Material | General Steel / Heat-Treated Steel / High-Hardness Steel ~ HRC55 / High-Hardness Steel ~ HRC60 / High-Hardness Steel – HRC65 / Acciaio inox / Ghisa | Number of Flutes(sheet) | 3 |

|---|---|---|---|---|---|

| Coating | For High Hardness (Silicone-Based) | Processing Applications | Curved Surface / Side Surface / Carving / R-Groove | Inventory Classification | Stocked Product |

| Torsion Availability | Included | Figure | 1 | Length Under Neck (θ)(Degree) | 10° |

Configura

Proprietà di base

-

R Size(mm)

-

Flute Length (ℓ)(mm)

-

Overall Length (L)(mm)

-

Length Under Neck (ℓ1)(mm)

-

Shank Diameter (d)(mm)

-

R Precision(μm)

-

Neck Gradient θ1

-

Tipo

- TSC-HBEM3PB

Filtrare per giorni di spedizione standard

-

- Tutti gli articoli

- 5 giorni o meno

Attributi opzionali

- Specifiche e dimensioni di alcuni componenti potrebbero non essere illustrate in modo esauriente. Per i dettagli esatti, consultare i cataloghi dei produttori .