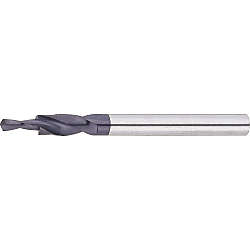

TiAlN Coated Carbide Stepped Drill, For Bolt Drilling / For Drilling Pilot Holes for Screws, with Chamfering Blade

Fare clic sull'immagine per ingrandirla.

Cliccare sull´immagine per ingrandirla.

- Sconto volumi elevati

Codice componente

Qui sono indicati i codici componente

correlati al prodotto ricercato

| Codice componente |

Prezzo unitario standard

| Quantità minima d'ordine | Sconto volumi elevati | Hole diameter (drill diameter) D (mm) | Groove Length L (mm) | Overall Length L (mm) | Step Length ℓ (mm) | Shank Diameter d | Diameter Tolerance | Tolerance of Shank Diameter | Use | Major Diameter D1 (φ) | Applicable Screw Size | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

90.07 € | 1 | Disponibile | 5 giorni | 3.4 | 21 | 73 | 8 | 6 | 0 ~ -0.014 | 0 ~ -0.008 | - | 6 | M4 | |

90.07 € | 1 | Disponibile | 5 giorni | 3.4 | 25 | 77 | 12 | 6 | 0 ~ -0.014 | 0 ~ -0.008 | - | 6 | M4 | |

97.21 € | 1 | Disponibile | 5 giorni | 4.3 | 26 | 79 | 10 | 7 | 0 ~ -0.014 | 0 ~ -0.009 | - | 7 | M5 | |

97.21 € | 1 | Disponibile | 5 giorni | 4.3 | 31 | 84 | 15 | 7 | 0 ~ -0.014 | 0 ~ -0.009 | - | 7 | M5 | |

110.88 € | 1 | Disponibile | 5 giorni | 5.1 | 30 | 84 | 12 | 8 | 0 ~ -0.014 | 0 ~ -0.009 | - | 8 | M6 | |

110.88 € | 1 | Disponibile | 5 giorni | 5.1 | 36 | 90 | 18 | 8 | 0 ~ -0.014 | 0 ~ -0.009 | - | 8 | M6 | |

130.21 € | 1 | Disponibile | 5 giorni | 6.8 | 40 | 96 | 16 | 10 | 0 ~ -0.018 | 0 ~ -0.009 | - | 10 | M8 | |

130.21 € | 1 | Disponibile | 5 giorni | 6.8 | 48 | 104 | 24 | 10 | 0 ~ -0.018 | 0 ~ -0.009 | - | 10 | M8 | |

94.01 € | 1 | Disponibile | 5 giorni | 8.5 | 50 | 112 | 20 | 12 | 0 ~ -0.018 | 0 ~ -0.011 | - | 12 | M10 | |

109.82 € | 1 | Disponibile | 5 giorni | 8.5 | 60 | 122 | 30 | 12 | 0 ~ -0.018 | 0 ~ -0.011 | - | 12 | M10 | |

107.98 € | 1 | Disponibile | 5 giorni | 10.3 | 60 | 124 | 24 | 14 | 0 ~ -0.022 | 0 ~ -0.011 | - | 14 | M12 | |

146.90 € | 1 | Disponibile | 5 giorni | 10.3 | 72 | 136 | 36 | 14 | 0 ~ -0.022 | 0 ~ -0.011 | - | 14 | M12 | |

85.47 € | 1 | Disponibile | 5 giorni | 3.4 | 21 | 73 | 8 | 6 | 0 ~ -0.014 | 0 ~ -0.008 | Cutting | 6 | - | |

95.93 € | 1 | Disponibile | 5 giorni | 3.4 | 21 | 75 | 10 | 6.5 | 0 ~ -0.014 | 0 ~ -0.009 | For Spot Facing | 6.5 | - | |

85.47 € | 1 | Disponibile | 5 giorni | 3.4 | 25 | 77 | 12 | 6 | 0 ~ -0.014 | 0 ~ -0.009 | Cutting | 6 | - | |

115.80 € | 1 | Disponibile | 5 giorni | 3.4 | 25 | 80 | 15 | 6.5 | 0 ~ -0.014 | 0 ~ -0.009 | For Spot Facing | 6.5 | - | |

84.87 € | 1 | Disponibile | 5 giorni | 4.3 | 26 | 79 | 10 | 7 | 0 ~ -0.014 | 0 ~ -0.009 | Cutting | 7 | - | |

111.45 € | 1 | Disponibile | 5 giorni | 4.5 | 25 | 74 | 12 | 8 | 0 ~ -0.014 | 0 ~ -0.009 | For Spot Facing | 8 | - | |

143.25 € | 1 | Disponibile | 5 giorni | 4.5 | 35 | 84 | 22 | 8 | 0 ~ -0.014 | 0 ~ -0.009 | For Spot Facing | 8 | - | |

110.88 € | 1 | Disponibile | 5 giorni | 5.1 | 30 | 84 | 12 | 8 | 0 ~ -0.014 | 0 ~ -0.009 | Cutting | 8 | - | |

110.88 € | 1 | Disponibile | 15 giorni | 5.1 | 36 | 90 | 18 | 8 | 0 ~ -0.014 | 0 ~ -0.009 | Cutting | 8 | - | |

128.10 € | 1 | Disponibile | 5 giorni | 5.5 | 29 | 79 | 17 | 9.5 | 0 ~ -0.014 | 0 ~ -0.009 | For Spot Facing | 9.5 | - | |

170.53 € | 1 | Disponibile | 5 giorni | 5.5 | 40 | 90 | 28 | 9.5 | 0 ~ -0.014 | 0 ~ -0.009 | For Spot Facing | 9.5 | - | |

209.17 € | 1 | Disponibile | 5 giorni | 6.6 | 32 | 91 | 20 | 11 | 0 ~ -0.018 | 0 ~ -0.011 | For Spot Facing | 11 | - | |

233.72 € | 1 | Disponibile | 5 giorni | 6.6 | 45 | 104 | 33 | 11 | 0 ~ -0.018 | 0 ~ -0.011 | For Spot Facing | 11 | - | |

130.21 € | 1 | Disponibile | 5 giorni | 6.8 | 40 | 96 | 16 | 10 | 0 ~ -0.018 | 0 ~ -0.009 | Cutting | 10 | - | |

109.82 € | 1 | Disponibile | 5 giorni | 8.5 | 60 | 122 | 30 | 12 | 0 ~ -0.018 | 0 ~ -0.011 | Cutting | 12 | - | |

190.12 € | 1 | Disponibile | 5 giorni | 9 | 47 | 108 | 28 | 14 | 0 ~ -0.018 | 0 ~ -0.011 | For Spot Facing | 14 | - | |

218.55 € | 1 | Disponibile | 5 giorni | 9 | 65 | 122 | 42 | 14 | 0 ~ -0.018 | 0 ~ -0.011 | For Spot Facing | 14 | - | |

146.90 € | 1 | Disponibile | 5 giorni | 10.3 | 72 | 136 | 36 | 14 | 0 ~ -0.022 | 0 ~ -0.011 | Cutting | 14 | - |

Loading...

Specifiche

Model Number

TAC-SF-SDR (For bolt hole drilling)

| Step Length ℓ | Large Diameter D1 | Groove Length ℓ1 | Overall Length L | Shank Diameter d | ||

| Tip Diameter D | ||||||

| Counterbore Type | 3.4 | 10 | 6.5 | 21 | 75 | 6.5 |

| 15 | 6.5 | 25 | 80 | 6.5 | ||

| 4.5 | 12 | 8 | 25 | 74 | 8 | |

| 22 | 8 | 35 | 84 | 8 | ||

| 5.5 | 17 | 9.5 | 29 | 79 | 9.5 | |

| 28 | 9.5 | 40 | 90 | 9.5 | ||

| 6.6 | 20 | 11 | 32 | 91 | 11 | |

| 33 | 11 | 45 | 104 | 11 | ||

| 9 | 28 | 14 | 47 | 108 | 14 | |

| 42 | 14 | 65 | 122 | 14 | ||

| Cutting Type | 3.4 | 8 | 6 | 21 | 73 | 6 |

| 12 | 6 | 25 | 77 | 6 | ||

| 4.3 | 10 | 7 | 26 | 79 | 7 | |

| 5.1 | 12 | 8 | 30 | 84 | 8 | |

| 18 | 8 | 36 | 90 | 8 | ||

| 6.8 | 16 | 10 | 40 | 96 | 10 | |

| 8.5 | 20 | 12 | 50 | 112 | 12 | |

| 30 | 12 | 60 | 122 | 12 | ||

| 10.3 | 36 | 14 | 72 | 136 | 14 |

| Tip Diameter D | Tolerance (h8) |

| 3.4 ~ 5.5 | 0 -0.014 |

| 6.6 ~ 9 | 0 -0.018 |

| 10.3 | 0 -0.022 |

| Shank Diameter d | Tolerance (h6) |

| 6 | 0 -0.008 |

| 6.5 ~ 10 | 0 -0.009 |

| 11~ 14 | 0 -0.011 |

Model Number

TAC-SC-SDR (For screw tap hole drilling)

| Tip Diameter D | Step Length ℓ | Large Diameter D1 | Groove Length ℓ1 | Overall Length L | Shank Diameter d | Applicable Screw Size |

| 3.4 | 8 | 6 | 21 | 73 | 6 | M4 |

| 12 | 6 | 25 | 77 | 6 | M4 | |

| 4.3 | 10 | 7 | 26 | 79 | 7 | M5 |

| 15 | 7 | 31 | 84 | 7 | M5 | |

| 5.1 | 12 | 8 | 30 | 84 | 8 | M6 |

| 18 | 8 | 36 | 90 | 8 | M6 | |

| 6.8 | 16 | 10 | 40 | 96 | 10 | M8 |

| 24 | 10 | 48 | 104 | 10 | M8 | |

| 8.5 | 20 | 12 | 50 | 112 | 12 | M10 |

| 30 | 12 | 60 | 122 | 12 | M10 | |

| 10.3 | 24 | 14 | 60 | 124 | 14 | M12 |

| 36 | 14 | 72 | 136 | 14 | M12 |

| Tip Diameter D | Tolerance (h8) |

| 3.4 ~ 5.1 | 0 -0.014 |

| 6.8 / 8.5 | 0 -0.018 |

| 10.3 | 0 -0.022 |

| Shank Diameter d | Tolerance (h6) |

| 6 | 0 -0.008 |

| 7 ~ 10 | 0 -0.009 |

| 12 / 14 | 0 -0.011 |

For Cutting Conditions, Refer to >>Click here.

Più Informazioni

● Boring and counterboring processes when drilling bolt holes can be done in a single step to realize a high-efficiency process. (Counterbore Model)

● When drilling pilot tap holes, a relief hole can be drilled at the same time, which is ideal for drilling pilot holes in thick sheet metal to provide scrap clearance. (Cutting Model)

● Designed for very frequent drilling of pilot holes for M4 – M12 metric coarse thread.

● High-efficiency hole drilling is achieved by reducing the chamfering process.

Informazioni di base

| work material | General Steel / Heat-Treated Steel / Acciaio inox / Ghisa / Alluminio / Rame | Tool Material Type | Carburo | Shank Type | Straight Shank |

|---|---|---|---|---|---|

| Coating Y/N | Included | Coating Type | TiAlN | With/without Oil Hole | None |

| Point Angle(°) | 140 | Thinning | Included |

Configura

Proprietà di base

-

Hole diameter (drill diameter) D(mm)

-

Groove Length L(mm)

-

Overall Length L(mm)

-

Step Length ℓ(mm)

-

Tipo

- TAC-SC-SDR

- TAC-SF-SDR

Filtrare per giorni di spedizione standard

-

- Tutti gli articoli

- 5 giorni o meno

- 15 giorni o meno

Attributi opzionali

- Specifiche e dimensioni di alcuni componenti potrebbero non essere illustrate in modo esauriente. Per i dettagli esatti, consultare i cataloghi dei produttori .