REAR, cilindro sinusoidale senza stelo, montaggio diretto (Codici componente - Download CAD)

[Features]

· Select a maximum speed of 300 mm/s or 600 mm/s.

· The cylinder can be mounted directly.

· Auto switches can be mounted without protruding from the cylinder.

· Compact external appearance.

· The body mounting surface can be the top surface or one side surface.

[Applications]

· Use for extremely tight spaces.

(i)Nota

- Refer to the manufacturer's catalog for specification and material details.

- Product images may be representative images. Refer to the manufacturer's catalog for shape details.

- CAD data is not supported for some model numbers.

Codice componente

Qui sono indicati i codici componente

correlati al prodotto ricercato

Sine Rodless Cylinder, Direct Mount Type REAR Series Details

Sine Rodless Cylinder, direct mount type, REAR Series product image

Sine Rodless Cylinder, Direct Mount Type REAR Series Specifications

| Tube Inner Diameter (mm) | 10 | 15 | 20 | 25 | 32 | 40 |

|---|---|---|---|---|---|---|

| Fluid | Air | |||||

| Guaranteed Proof Pressure | 1.05 MPa | |||||

| Maximum Operating Pressure | 0.7 MPa | |||||

| Minimum Operating Pressure | 0.18 MPa | |||||

| Ambient Temperature and Operating Fluid Temperature | -10°C to 60°C (no freezing) | |||||

| Piston Speed (Max) * | 50 to 300 mm/s | |||||

| Lubrication | Not required (non-lube) | |||||

| Stroke Length Tolerance (mm) | 0 to 250 st: (0 to +1.0), 251 to 1,000 st: (0 to +1.4), 1,001 st and above: (0 to +1.8), | |||||

| Holding Force (N) | 53.9 | 137 | 231 | 363 | 588 | 922 |

*The operating piston speed above indicates the maximum speed. From the beginning of body movement at the stroke end until the end of the cushion stroke takes approx. 0.5 seconds (one side) or 1 second for both sides.

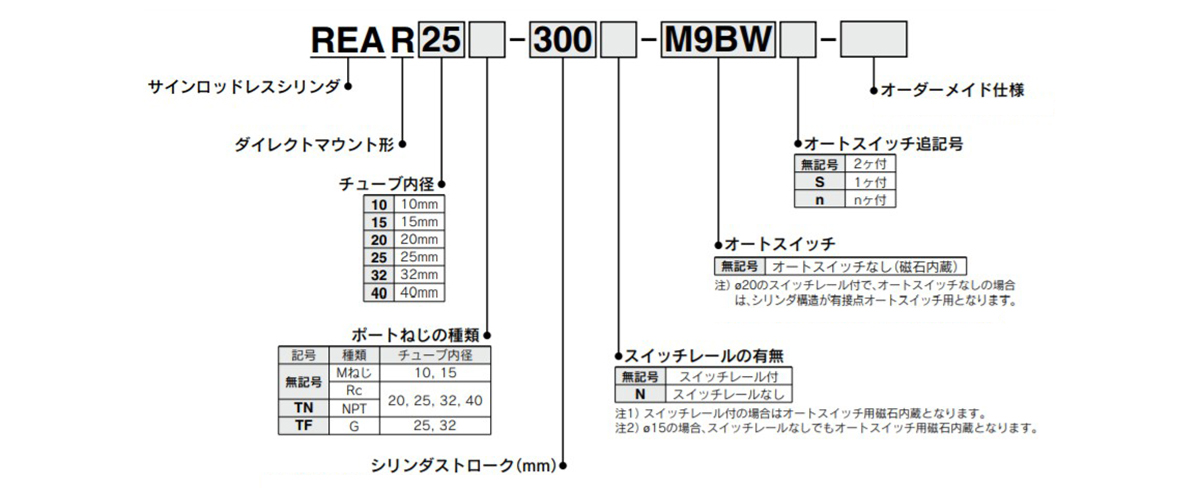

Model Number Notation

Model number examples

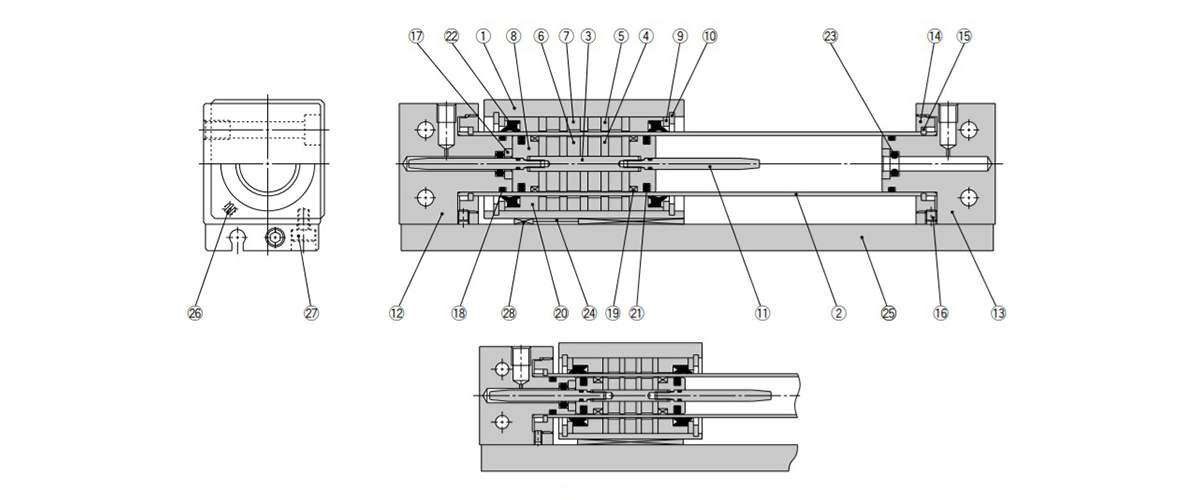

Structural Drawing Examples

ø10 mm / ø15 mm structural drawing

Component Parts

| Number | Part name | Material | Note |

|---|---|---|---|

| 1 | Body | Aluminum alloy | Hard Anodize |

| 2 | Cylinder Tube | Stainless steel | - |

| 3 | Shaft | Stainless steel | - |

| 4 | Piston-Side Yoke | Rolled steel plate | Zinc chromate |

| 5 | External Slider Side Yoke | Rolled steel plate | Zinc chromate |

| 6 | Magnet A | - | - |

| 7 | Magnet B | - | - |

| 8 | Piston | Aluminum alloy | Chromate |

| 9 | Spacer | Rolled steel plate | Nickel plating |

| 10 | Retaining Ring | Carbon tool steel | Phosphate conversion coating |

| 11 | Cushion Ring | Stainless steel | - |

| 12 | End Cover A | Aluminum alloy | Hard Anodize |

| 13 | End Cover B | Aluminum alloy | Hard Anodize |

| 14 | Attachment Ring | Aluminum alloy | Hard Anodize |

| 15 | Type C Retaining Ring for Shaft | Stainless steel | REAR10 |

| High carbon steel wire material | Nickel plating (REAR15) | ||

| 16 | Hex Socket Head Set Screw | Chromium steel | Nickel plating |

| 17 | Holding Plate | Aluminum alloy | - |

| *18 | Cylinder Tube Gasket | NBR | - |

| *19 | Wear Ring A | Special resin | - |

| *20 | Wear Ring B | Special resin | - |

| *21 | Piston Seal | NBR | - |

| *22 | Scraper | NBR | - |

| *23 | Cushion Seal | NBR | - |

| 24 | Magnetic Shielding Plate | Rolled steel plate | Bright chromate |

| 25 | Switch Rail | Aluminum alloy | Clear anodizing |

| 26 | Magnet | - | - |

| 27 | Hexagon Socket Head Bolt | Chromium steel | Nickel plating |

| *28 | Wear Ring C | Special resin | - |

Replacement Parts / Seal Kit

| Tube Internal Diameter (mm) | Order Number | Content |

|---|---|---|

| 10 | REAR10-PS | *1, *2 Set of above numbers (18), (20), (21), (22), (23), (28) |

| 15 | REAR15-PS | *1 Set of above numbers (18), (19), (20), (21), (22), (23), (28) |

*1: The (23) cushion seal may be difficult to replace.

*2: Contact SMC when replacing the ø10‑mm (19) wear ring A.

- *The seal kit includes a grease pack (5 g and 10 g for ø10 mm, 10 g for ø15 mm).

- *Order with the following part number when only the grease pack is needed.

øGrease pack part number for ø10 mm: GR-F-005 (5 g) for external sliding part / GR-S-010 (10 g) for tube interior

øGrease pack part number for ø15 mm: GR-S-010 (10 g)

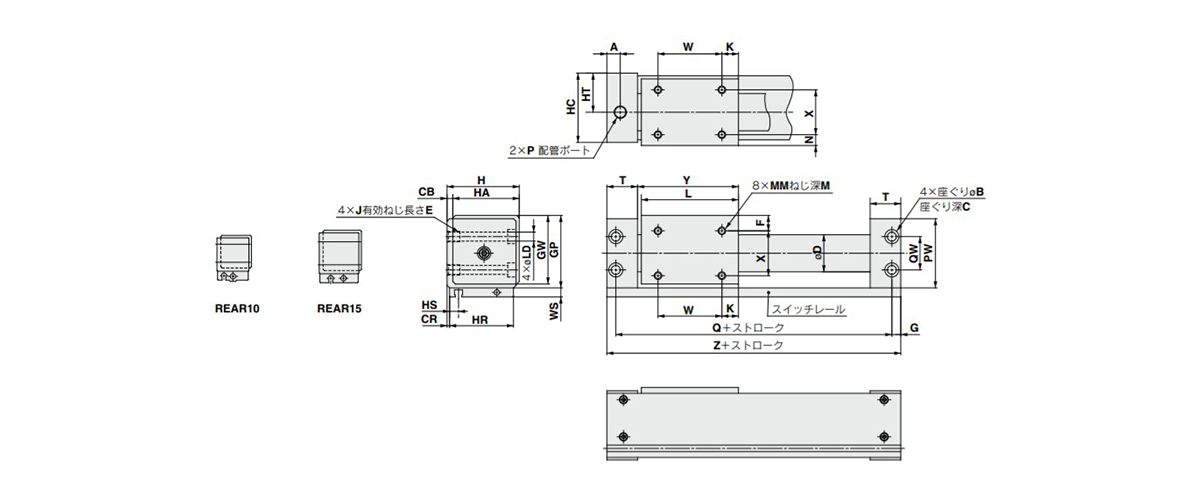

Sine Rodless Cylinder, Direct Mount Type REAR Series Dimensions

(Unit: mm)

Sine Rodless Cylinder, direct mount type, REAR Series dimensional drawing

| Model | A | B | C | CB | CR | D | F | G | GP | GW | H | HA | HC | HR | HS | HT | J ×; E |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| REAR10 | 10.5 | 6.5 | 3.2 | 2 | 0.5 | 12 | 6.5 | 6 | 27 | 25.5 | 26 | 24 | 25 | 24 | 5 | 14 | M4 ×; 0.7 ×; 6 |

| REAR15 | 12 | 8 | 4.2 | 2 | 0.5 | 17 | 8 | 7 | 33 | 31.5 | 32 | 30 | 31 | 30 | 8.5 | 17 | M5 ×; 0.8 ×; 7 |

| REAR20 | 9 | 9.5 | 5.2 | 3 | 1 | 22.8 | 9 | 6 | 39 | 37.5 | 39 | 36 | 38 | 36 | 7.5 | 21 | M6 ×; 1 ×; 8 |

| REAR25 | 8.5 | 9.5 | 5.2 | 3 | 1 | 27.8 | 8.5 | 6 | 44 | 42.5 | 44 | 41 | 43 | 41 | 6.5 | 23.5 | M6 ×; 1 ×; 8 |

| REAR32 | 10.5 | 11 | 6.5 | 3 | 1.5 | 35 | 10.5 | 7 | 55 | 53.5 | 55 | 52 | 54 | 51 | 7 | 29 | M8 ×; 1.25 ×; 10 |

| REAR40 | 10 | 11 | 6.5 | 5 | 2 | 43 | 13 | 7 | 65 | 63.5 | 67 | 62 | 66 | 62 | 8 | 36 | M8 ×; 1.25 ×; 10 |

| Model | K | L | LD | M | MM | N | P | PW | Q | QW | T | W | WS | X | Y | Z | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| No Symbol | TN | TF | ||||||||||||||||

| REAR10 | 9 | 38 | 3.5 | 4 | M3 ×; 0.5 | 4.5 | M5 ×; 0.8 | - | - | 26 | 68 | 14 | 19.5 | 20 | 8 | 15 | 39.5 | 80 |

| REAR15 | 14 | 53 | 4.3 | 5 | M4 ×; 0.7 | 6 | M5 ×; 0.8 | - | - | 32 | 84 | 18 | 21 | 25 | 7 | 18 | 54.5 | 98 |

| REAR20 | 11 | 62 | 5.6 | 5 | M4 ×; 0.7 | 7 | Rc 1/8 | NPT 1/8 | - | 38 | 95 | 17 | 20.5 | 40 | 7 | 22 | 64 | 107 |

| REAR25 | 15 | 70 | 5.6 | 6 | M5 ×; 0.8 | 6.5 | Rc 1/8 | NPT 1/8 | G 1/8 | 43 | 105 | 20 | 21.5 | 40 | 7 | 28 | 72 | 117 |

| REAR32 | 13 | 76 | 7 | 7 | M6 ×; 1 | 8.5 | Rc 1/8 | NPT 1/8 | G 1/8 | 54 | 116 | 26 | 24 | 50 | 7 | 35 | 79 | 130 |

| REAR40 | 15 | 90 | 7 | 8 | M6 ×; 1 | 11 | Rc1/4 | NPT 1/4 | - | 64 | 134 | 34 | 26 | 60 | 7 | 40 | 93 | 148 |

Codice componente

|

|---|

| REAR25-1500 |

| REAR32-1500 |

| Codice componente |

Prezzo unitario standard

| Quantità minima d'ordine | Sconto volumi elevati | Corsa (mm) | Max. Massa di carico (gamma selezionabile) (kg) | Max. Massa di carico (kg) | Lunghezza tavola L (mm) | D.I. cilindro (Ø) | Velocità d'esercizio (mm/s) | Larghezza tavola W (mm) | Altezza tavola H (mm) | Pressione di esercizio (MPa) | Port Screw Type | Auto Switch | Lead Wire Length (m) | Number of Switches | Custom-made Specifications | End Block | Model | Stroke Adjustment Unit Symbol | Custom-made | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

1,305.60 € | 1 | 26 giorni | 1,500 | 1 to 4.9 | 1.2 | 70 | 25 | - | 42.5 | 44 | - | Rc | Sì | Magnete incorporato | Assente | - | - | - | 0.18–0.7 | Assente | ||

1,676.90 € | 1 | 26 giorni | 1,500 | 1 to 4.9 | 1.5 | 76 | 32 | - | 53.5 | 55 | - | Rc | Sì | Magnete incorporato | Assente | - | - | - | 0.18–0.7 | Assente |

Loading...

Informazioni di base

| Tipo | “Cilindro senza asta” | Materiale tavola | Lega di alluminio | Giunto cilindro senza barra | Magnetico |

|---|---|---|---|---|---|

| Ambiente d'esercizio | Uso generico | Trattamento superficie tavola | Alluminio anodizzato duro | Guida | Montaggio diretto |

Configura

Proprietà di base

-

Max. Massa di carico (gamma selezionabile)(kg)

-

Max. Massa di carico(kg)

-

Lunghezza tavola L(mm)

-

D.I. cilindro(Ø)

-

Larghezza tavola W(mm)

-

Altezza tavola H(mm)

-

Pressione di esercizio(MPa)

-

Port Screw Type

- G

- Rc

- Vite M

-

Auto Switch

- Assente

- Nessuno

- Sì

-

Lead Wire Length(m)

-

Number of Switches

-

Custom-made Specifications

- 0.5

- 3

- Assente

-

End Block

- Assente

-

Model

-

Stroke Adjustment Unit Symbol

- 0.18–0.7

-

Custom-made

- Assente

- Cilindro senza stelo con snodo flottante

-

Tipo

- REAR

- REAR10

- REAR15

- REAR20

- REAR25

- REAR32

-

Corsa(mm)

-

Filtrare per tipo dati CAD

- 2D

- 3D

Filtrare per giorni di spedizione standard

-

- Tutti gli articoli

- 4 giorni o meno

- 18 giorni o meno

- 26 giorni o meno

Attributi opzionali

- CAD data is not supported for some model numbers.

- Specifiche e dimensioni di alcuni componenti potrebbero non essere illustrate in modo esauriente. Per i dettagli esatti, consultare i cataloghi dei produttori .