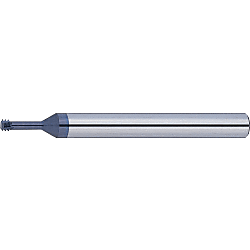

TiAlN Coated Carbide Threading Cutter, for High-Hardness Steel / for Internal Metric Threads (HMINMT-M12-1.75-24)

- Sconto volumi elevati

Dettagli del prodotto:

Codice articolo del costruttore: HMINMT-M12-1.75-24

Marca: MISUMI

Prezzo: 347.87 €

Tempi di consegna: 7 giorni

Dati Tecnici:

Nominal: M12

Pitch, Number of Threads: 1.75 mm

Overall Length (L): 73 mm

Maximum Processing Thread Depth: 24 mm

Major Diameter: 9 φ

Codice componente

Qui sono indicati i codici componente

correlati al prodotto ricercato

HMINMT-M12-1.75-24

Codice componente

|

|---|

| HMINMT-M12-1.75-24 |

| Codice componente |

Prezzo unitario standard

| Quantità minima d'ordine | Sconto volumi elevati | Nominal | Pitch, Number of Threads (mm) | Overall Length (L) (mm) | Maximum Processing Thread Depth (mm) | Major Diameter (φ) | Shank Diameter (φ) | Length Under Neck (mm) | |

|---|---|---|---|---|---|---|---|---|---|---|---|

347.87 € | 1 | Disponibile | 7 giorni | M12 | 1.75 | 73 | 24 | 9 | 10 | 26 |

Loading...

Specifiche

Model Number

HMINMT

| Nominal M x P |

Maximum Machining Thread Depth |

Major Diameter D |

Overall Length L |

Length Under Neck ℓ |

Shank Diameter d |

Cutting Edge Thread No. |

No. of Grooves | |

| M2 | 0.4 | 4 | 1.55 | 58 | 4.5 | 6 | 3 | 3 |

| M2.2 | 0.45 | 4.5 | 1.65 | 58 | 5 | 6 | ||

| M2.5 | 0.45 | 5 | 1.95 | 58 | 5.5 | 6 | ||

| M2.5 | 0.45 | 7 | 1.95 | 58 | 7.5 | 6 | ||

| M3 | 0.5 | 6 | 2.35 | 58 | 6.5 | 6 | ||

| M3 | 0.5 | 9 | 2.35 | 58 | 9.5 | 6 | ||

| M3.5 | 0.6 | 7 | 2.75 | 58 | 7.5 | 6 | ||

| M4 | 0.7 | 8 | 3.1 | 58 | 9 | 6 | ||

| M4 | 0.7 | 12 | 3.1 | 58 | 12.5 | 6 | ||

| M5 | 0.8 | 10 | 3.8 | 58 | 12.5 | 6 | ||

| M5 | 0.8 | 15 | 3.8 | 58 | 16 | 6 | ||

| M6 | 1 | 12 | 4.65 | 58 | 14 | 6 | ||

| M6 | 1 | 18 | 4.65 | 58 | 20 | 6 | ||

| M8 | 1.25 | 16 | 5.95 | 58 | 18 | 6 | ||

| M8 | 1.25 | 24 | 5.95 | 58 | 24 | 6 | ||

| M10 | 1.5 | 20 | 7.8 | 64 | 23 | 8 | ||

| M12 | 1.75 | 24 | 9. | 73 | 26 | 10 | ||

[ ! ]You can use this cutter for left-handed rotation.

Take sufficient care when making the program settings.

Più Informazioni

● The left-flute left-rotary cutting that is achieved by the original flute shape and coating allow the milling threading of high hardness steel of up to HRC62.

● Small diameter threading is possible from M2x0.4 (pilot hole diameter Ø 1.6 mm).

● The processing time is reduced since high speed cutting is possible.

● The effective thread can be cut all the way to the corners of the blind hole.

■Misumi Threading Cutter Product CNC Program Download Services

Informazioni di base

| Thread Types | Tipo metrico | Tool Material Type | Carburo | Work Material | Low-Carbon Steel (C Content of 0.25% or Less) / Medium-Carbon Steel (C Content 0.25 - 0.45%) / High-Carbon Steel (C Content Exceeding 0.45%) / Acciaio legato (SCM) / Stainless Steel (SUS) / Heat-Treated Steel (25 - 35 HRC) / Heat-Treated Steel (35 - 45 HRC) / Heat-Treated Steel (45 - 55 HRC) / High-Hardness Steel (50 - 60 HRC) / Tool Steel (Before SKD Quenching) / Cast Steel (SC) / Ghisa (FC) / Ghisa duttile (FCD) / Rame (Cu) / Ottone (Bs) / Brass Cast Iron (BsC) / Bronze (PB) / Rolled Aluminum Material (AL) |

|---|---|---|---|---|---|

| Tap Model | Tapping Cutter | Bore Model | For Through Holes / For Blind Holes | Coating Presence | Included |

| Surface treatment | TiAlN | No. of Grooves | 3 | Number of Blade Teeth | 3 |

Configura

Proprietà di base

-

Tipo

- HMINMT

-

Nominal

-

Pitch, Number of Threads(mm)

-

Overall Length (L)(mm)

-

Maximum Processing Thread Depth(mm)

-

Major Diameter(φ)

-

Shank Diameter(φ)

-

Length Under Neck(mm)

Filtrare per giorni di spedizione standard

-

- Tutti gli articoli

- 7 giorni o meno

Attributi opzionali

- Specifiche e dimensioni di alcuni componenti potrebbero non essere illustrate in modo esauriente. Per i dettagli esatti, consultare i cataloghi dei produttori .